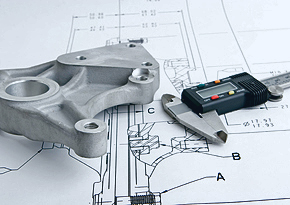

Design / Engineering

High quality parts start with advanced engineering. To ensure quality and precision in every product we make, Dynamic Plastics utilizes the latest Mold Flow analysis software, advanced CAD and CAM software, and state-of-the-art High Speed Machining Centers and CNC machinery. Equipped with these tools, our knowledgeable engineering staff is able to provide the insight and support necessary to move your project from initial concept to high quality plastic components.

At the critical early stages of your project, our team is able to offer feedback on part design, help identify potential trouble areas, and propose the optimal gate area for your part by utilizing our Mold Flow software as well as our many years of practical experience.

We use top-of-the-line CAD software—including Unigraphics, Solidworks, and Mastercam—to provide a comprehensive mold design that is created directly from your part data. This ensures the utmost in quality and accuracy as we are working directly from the part model you provide to us.

We work directly from the mold design using Camtool and Mastercam CAM software to generate cutter paths for our High Speed Machining Centers and CNC machines. By using the cutter path that has been created, we are then able to quickly and accurately machine the high quality tooling to produce your parts.

For more information about design considerations for plastic components, please review our Plastic Design Guide. If you’d like more information about popular resins, please consult our Basic Resin Guide.