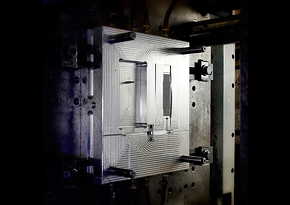

Molding

Dynamic Plastics offers molding services that encompass a large variety of parts in many shapes and sizes. With molding presses that range from 75 to 1100 tons in clamping force and capabilities extending to 2000 tons through local partnerships, we are equipped to mold parts for a variety of applications and industries. We support Dimensional, Cosmetic, Insert Molded, and Overmolding of parts to name just a few, and are able to provide them in any volume you need. Our experienced and well trained process engineers are dedicated to providing exceptional service and quality. Using their ability to establish optimal and repeatable molding processes, our team will ensure that you receive the highest quality parts each and every time. Whether your need is Prototype, Low Volume Production, Production, or even to Transfer an existing tool or program, Dynamic Plastics can provide the solution you need to set yourself apart.

The molding solutions that we provide include:

- Prototype: Aluminum or P-20 steel tools are used to quickly provide high quality parts in lower volumes, and our many years of experience in prototype molding allow us to process production quality parts to quickly and accurately provide our customers the competitive edge they need.

- Low Volume Production: Aluminum or P-20 Steel tooling is utilized to provide you with an excellent and cost-effective option to produce production parts in volumes of up to 250,000 pieces. Why pay for tooling that is built to run millions of pieces when we are able to provide a tooling solution that we will guarantee for your lower volumes? The same molding standards and processes that are applied to High Volume Production are used to ensure you receive the highest quality parts available.

- High Volume Production: This option utilizes single and multi-cavity P-20 or hardened S-7 tooling that is capable of sustaining very high volumes. Our team of process engineers will work with our Quality Assurance Department to establish strictly controlled, well documented processes that will ensure the highest quality and repeatability for your high volume projects.

- Transfer Tooling: Having trouble with a current vendor, or just looking for a home for an existing mold or program? Dynamic Plastics welcomes the opportunity to provide a molding solution for you. Let our ability to transfer tools and bring them into production quickly be an asset to you.