| Tooling | |

| Molding | |

| Design/Engineering | |

| Value Added Services | |

| Quality Systems |

The Dynamic Advantage Means Better Tooling

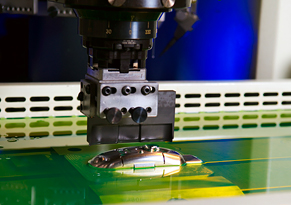

Dynamic Plastics retains a highly skilled tool manufacturing team that will work with you to develop high quality components and products that are built to your specifications. With a variety of tooling options to offer, we can provide you with the right solution to fit your requirements, whatever they may be. Our modern, well-equipped tool room includes the latest in high-speed CNC machining centers, orbital CNC EDM machines, and CNC Wire EDM machines that enable us to machine even the most complex details to meet your exacting standards. Utilizing the latest CAD and CAM software, we design and build every tool directly from the part file or part print that is provided by the customer. This ensures that the products you receive are of the highest quality and accuracy available regardless of the tooling option you may require.

The types of tooling options that we offer include:

-

Prototype Tooling:

Typically constructed of aluminum, and often with deliveries as fast as 2 to 3 weeks. This is a great option for customers seeking high quality parts in relatively low volumes quickly.

-

Bridge Tooling:

A hybrid solution for customers seeking tooling that is capable of sustaining higher volumes than true prototype tooling, should the need arise. Materials used for construction are usually aluminum or P-20 steel, depending upon the customer’s needs and expectations. This is a good choice for customers who may need to move quickly from prototype to low volume production.

-

Low Volume Production:

Normally produced from aluminum or p-20 steel, this type of tooling is generally designed and built to run automatically the same way a higher volume production tool would be. This is an excellent choice for customers that intend to go into production of up to 250,000 pieces and is a very popular selection due to the combination of quality, durability, and price.

-

Production:

Single or multi-cavity automatic tools usually constructed of P-20 or hardened S-7 steel, this is a good choice for customers seeking very high volumes.